Danish Corrosion Control

Main menu

- D*C*C* Home

- About D*C*C*

- Inspection

- Riding crews

- Training courses

- Reference

- Contact details

UHP blasting

UHP Larger areas:

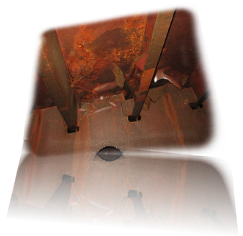

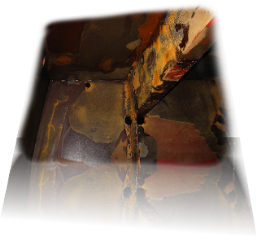

In order to achieve a chloride free surface and allowing our crew to work efficiently at sea, DCC uses ultra high pressure (UHP) hydro-

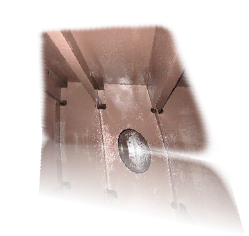

Also stainless steel cargo tanks and piping can be fully cleaned/blasted successfully by means of UHPwith an appearance of "new" as a result.

Why Blast with UHP on Voyage?

Consistently good quality result and good paint adhesion as surface related chlorides are removed along with all corrosion

Environmentally sound method

Dustfree work

No extra demucking

No additional disposalproblems

Cost per m2 is significantly less than if done at a shipyard

No shipyard/dock or port costs

No offhire as all the work is done while the ship is trading

UHP blasting & Recoating – How?

Surface cleaned to chloride free bare steel using UHP hydroblasting (up to 3000 bar)

Areas dried out using industrial size dehumidifiers

New coating applied according to the standards supplied by the paintsupplier

TheDCC crew and equipment is mobilized in a port convenient to the ships schedule

A crew typically consists of 4 to 8 people working 3-

4 months on/off schedule The crew are experienced UHP hydroblasters and painters

Project duration is normally 6 to 20 months

Weekly progress reports

Daily logs regards to paint application