Danish Corrosion Control

Main menu

- D*C*C* Home

- About D*C*C*

- Inspection

- Riding crews

- Training courses

- Reference

- Contact details

Sand washing

Sandwashing spot repair:

D*C*C* typically place a repair crew of 2 to X amount of people on board the vessel, along with a full complement of sandwashing equipment and HP high pressure washing machines, power tools, dehumidifiers, air-

Why sandwash on Voyage?

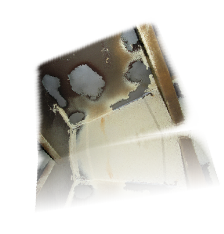

Consistently good quality result and good paint adhesion as surface embedded chlorides are removed along with all corrosion

Overlap zones into existing coating is abraded by means of the “quarts sand”

The use of quarts sand (non metallic grit) means ballast system will stay unharmed

Cost per m2 is significantly less than if done at a shipyard or by means of UHP blasting

No shipyard/dock or port costs

No offhire costs as all the work is done while the ship is trading regularly and make earnings.

Sandwashing & Recoating – How?

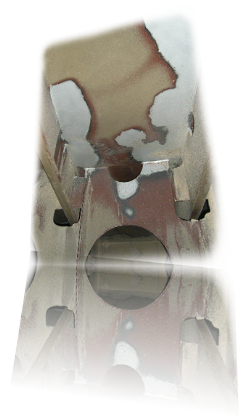

Corroded and blistered areas removed and surface cleaned to chloride free bare steel

Additional roughness applied to areas without excisting roughness

Overlap zones abraded, creates a perfect key for the new coating

HP wash all affected areas

Areas dried out using industrial size dehumidifiers

New coating applied according to the standards supplied by the paintsupplier

The DCC crew and equipment is mobilized in a port convenient to the ships schedule

A crew typically consists of 2 to 8 people working 3-

4 months on/off schedule The crew are all experienced in sandwashing, hydroblasting and paint application

Project duration is normally 6 to 20 months

Weekly progress reports

Daily logs regards to paint application